Application scope

Falling film evaporator widely used in fresh milk,tomato juice,soybean milk,xylitik,sirbitol,VC, honey,starch sugar,fructose,glucose,drink etc heat sensitive material concentration. Equipment working under vacuum with low temperature evaporation in short time,it will keep material original flavor, and feed,discharge continuously,easy to operate,maintain and cleaning. Also used in waste water treatment of monosodium glutamate,ethyl alcohol,fish meal etc. And many industries,such as food,medicine,biology chemical engineering,environmental engineering, chemical etc.

System component

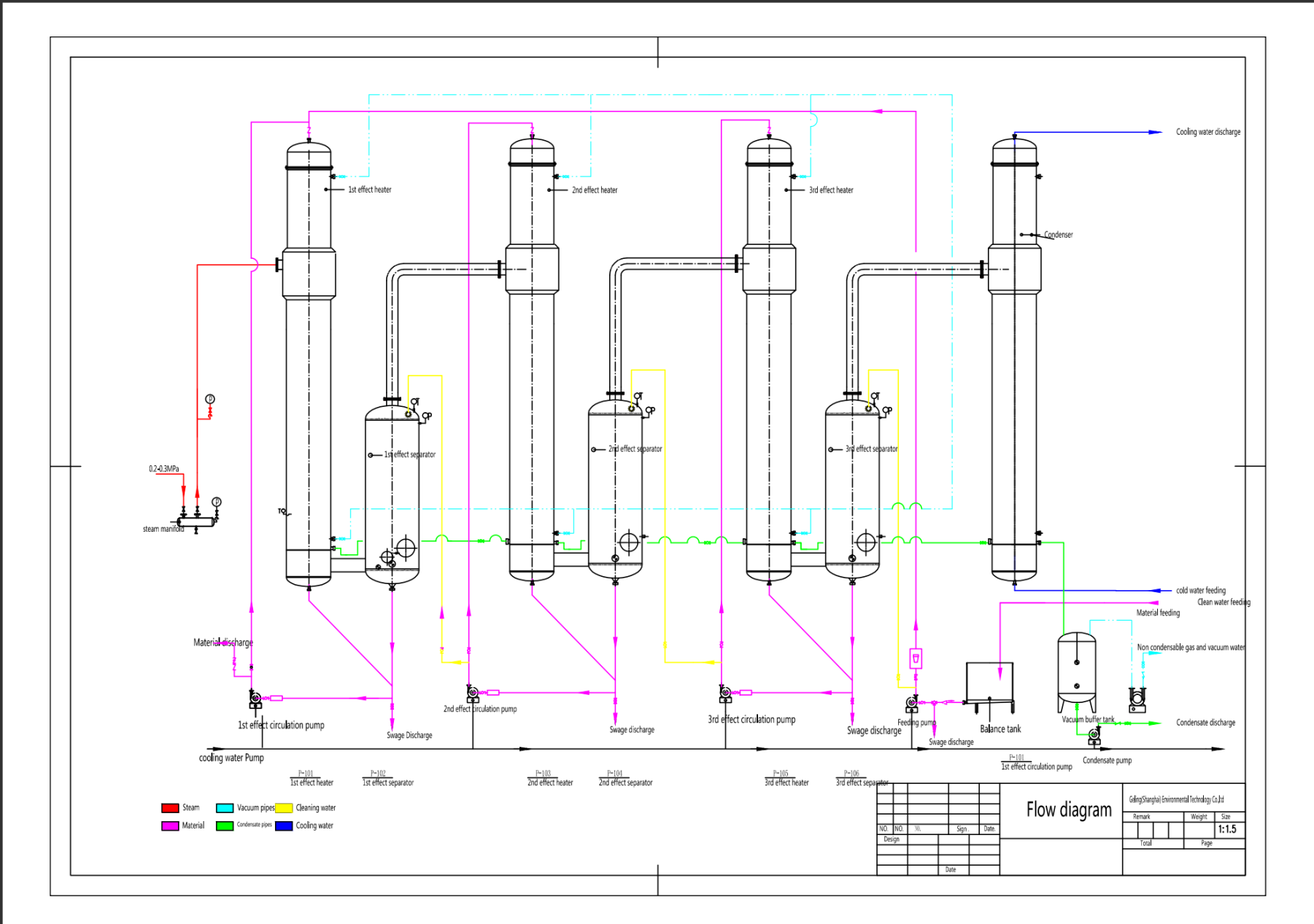

every effect heater, every effect separator,condenser, TVR(heat pump),sterilizer,insulation pipeline,vacuum system,each effect transfer pump,condensate pump,operation platform,electric instrument control cabinet,pipeline etc.

Multi-effect evaporation concentration equipment

The new steam enters the first effect as a heat source, and the generated secondary steam is introduced into the second effect, and so on. Multiple evaporators are connected and operated together to form a multi effect evaporation system. In a multi effect evaporation system, the latent heat of steam is reused, which can significantly reduce the amount of thermal energy consumption, greatly reduce energy consumption, and improve thermal efficiency.

- Commonly used evaporation and concentration equipment

- As the number of effectors increases, steam consumption becomes more economical.

- Although the equipment investment cost is relatively low, it brings a significant energy burden due to the consumption of a large amount of steam.

- Suitable for concentrated evaporation crystallization in situations where steam prices are low.

Beside this sheet , we also can design according to client different requirement with different proposal .

|

Model of machine |

Single effect |

Double effect |

Triple effect |

Four effect |

Five effect |

Six effect |

Seven Effect |

Eight effect |

|

Water evaporation capacity –T/ hr |

0.5 ~2 |

1.2~5 |

3.6~20 |

12~120 |

20~180 |

80~900 |

||

|

Solution feeding concentration — Brix / % |

These all depend on the different material |

|||||||

|

Solution discharge concentration –Brix / % |

||||||||

|

Steam Pressure –Mpa |

0.05~0.1 |

0.6~0.8 |

0.09~0.4 |

|||||

|

Steam consumption –kg / hr |

1.13 |

0.38~0.57 |

0.28~0.38 |

0.23~0.28 |

0.23 |

0.2 |

0.175 |

0.155 |

|

Evaporation temperature –℃ |

48~110 |

|||||||

|

Cooling water circulation using consumption –Tons ( Feeding temp . as 30 ℃ , discharge temp. As 38 ℃) |

56 |

18~28 |

14~18 |

12~14 |

10~12 |

9~10 |

8~9 |

7~8 |

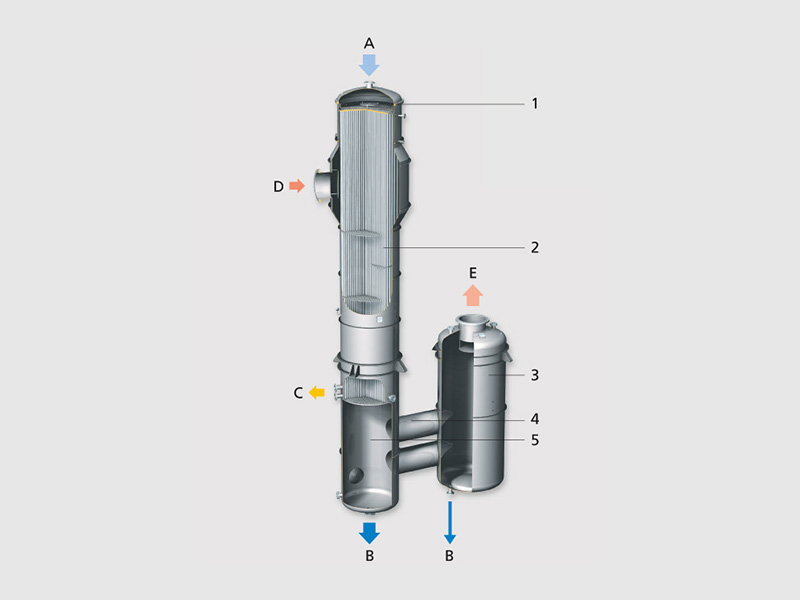

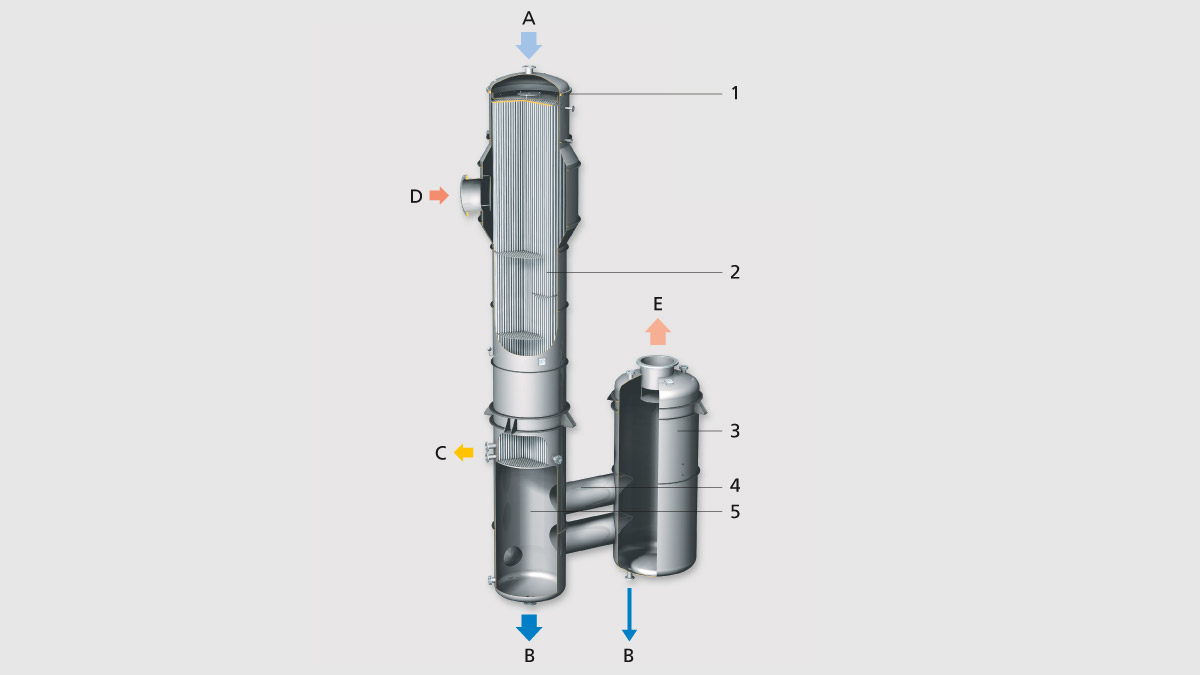

effect falling film evaporator process diagram

Including falling film evaporator and forced falling film evaporator, the heat transfer components include two types of heat transfer structures: tube type and plate type these two kinds method .

Tubular falling film evaporator is the process of adding material and liquid from the upper box of the heating chamber of the falling film evaporator, evenly distributing them into each heat exchange tube through a liquid distributor, and forming a uniform film like flow from top to bottom under the action of gravity and airflow. During the flow process, it is heated and vaporized by the shell side heating medium, and the generated steam and liquid phase jointly enter the separation chamber of the evaporator. After sufficient separation, the secondary steam and concentrated liquid are discharged separately.

Plate type falling film evaporator uses hollow plates as heat exchange elements. The liquid passes through the liquid distributor on the upper part of the heater group and forms a liquid film on the outer surface of each plate, which flows downwards by gravity. During the flow process, it is heated and vaporized by the heating medium in the plate cavity, and the generated secondary steam enters the shell. After being shared by the mist, it is discharged. The concentrated liquid enters the bottom of the shell and is discharged.

Forced falling film evaporator involves adding a large flow circulating pump to a regular falling film evaporator to increase the thickness of the liquid film and reduce scaling, which can reduce and prevent the phenomenon of “dry wall”.

Main characteristics

- The pump has a relatively small flow rate, low installed power, and low power consumption.

- High concentration ratio, falling film evaporation, and short concentration time.

Special design can achieve switching and efficiency improvement through simple operation to adapt to the production of different products.

- Spray feed at the top of the evaporator or use the multiple overflow film distribution device to ensure that the feed liquid is evenly distributed in the film tube of the evaporator, forming a film shape, greatly improving the heat transfer coefficient, increasing the evaporation rate, and preventing the “dry wall” phenomenon.

- After vapor liquid separation at the bottom of the evaporator, the feed liquid enters the separator for further separation, enhancing the separation effect.

- The large equipment adopts a vertical floor structure, with a compact structure, small footprint, and simple and smooth layout, representing the development of large complete sets of evaporation equipment.

Offering complete evaporation plant design, supply, installation, and start up services. Our equipment is designed in-house using the latest developments and technology in the market. Quality and performance is the focus for everything we build.